An Introduction to our Slitting Machine range

Universal Converting Equipment manufactures a range of slitter rewinders to meet the needs of a range of markets and budgets. We design and build all our machines and can customise them to meet specific requirements.

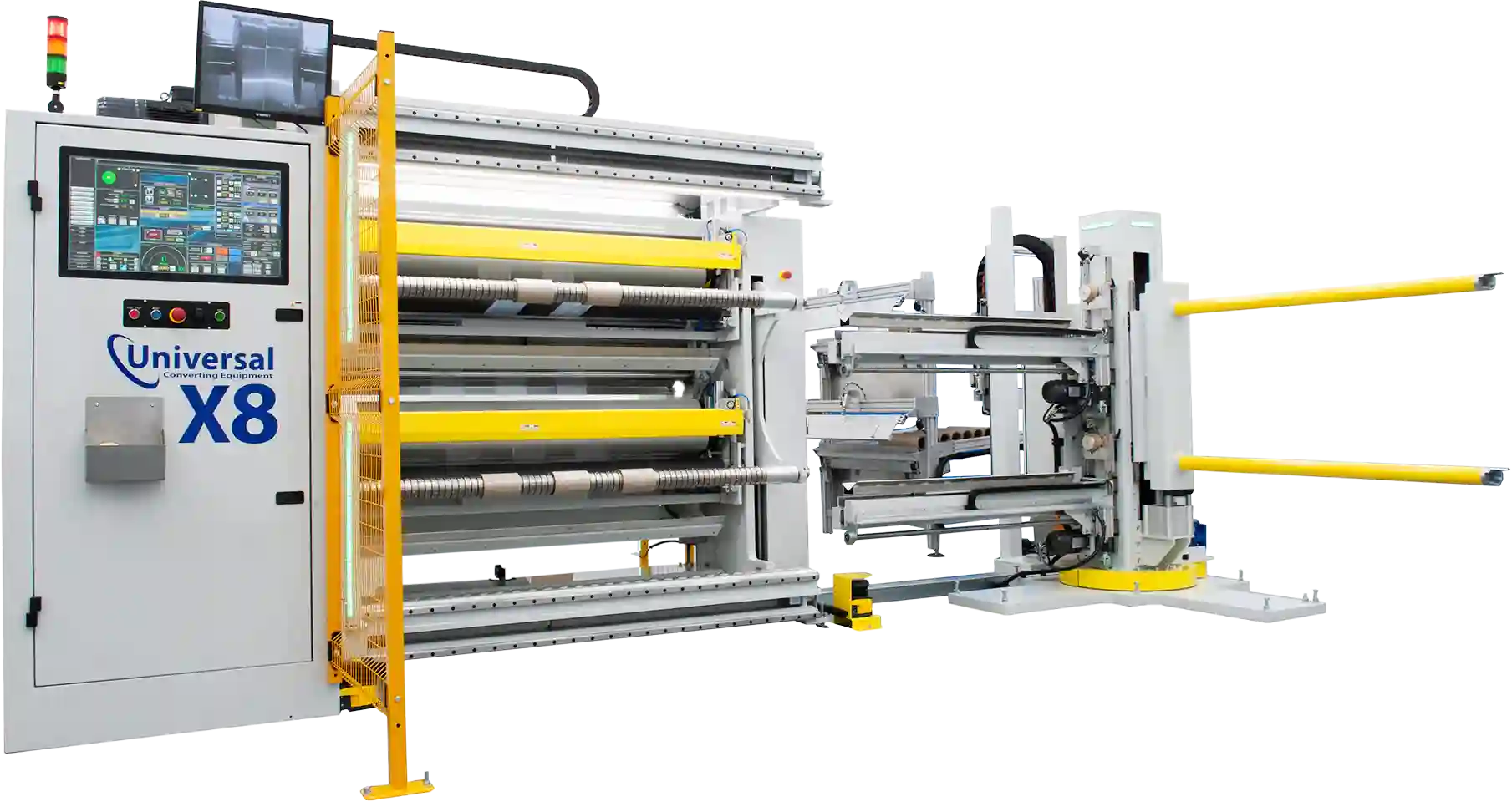

X8 Slitting Machine

Building on the success of the Universal X6 and X6VT models, the Universal X8 pushes the technology to the next level. It offers unmatched productivity while maintaining ease of use. With its advanced integrated systems, setup times for new products are significantly reduced and the transition between roll sets is our fastest yet.. The Universal X8 is engineered to handle tasks that can be more efficiently performed by the machine, maximising running time and freeing up operators to focus on other tasks.

X6 Slitting Machine

The Universal X6 slitting machine has been designed to produce perfect slit rolls time and time again. This versatile machine incorporates Universal’s closed loop Total Tension Control System, ensuring consistent and repeatable roll tension profiles. Using digital AC vector drives and integrated control system, the machine offers unprecedented control whilst being simple and friendly to operate. Technology is used to save time and improve accuracy resulting in higher productivity and improved quality.

X6t Slitting Machine

The Universal X6t slitter is a variant of the popular Universal X6 Flexible Materials slitter rewinder that has been designed to capitalise on the efficiency and accuracy features that make the X6 range an easy purchase, not just for converter of flexible packaging materials, but also for companies slitting foils, papers and a wide range of other materials. The turret capability of the X6t perfectly compliments the other automation options – including laser core alignment, automatic shear and razor knife positioning, automatic core positioning, end of roll cut off and off-loading pushers with roll handling- to produce levels of efficiency and operator simplicity surpassing many competitive machines.

X3 Narrow Width Compact Slitter

The Universal X3 is a compact slitter with a narrow width, offering capabilities comparable to larger slitter rewinders. Its small footprint, accurate tension control, and high-speed capability make it ideal for narrow-width slitting applications, especially for customers with limited floor space. The X3 features edge line guiding, optional lay-on arms, and differential shafts, with a design that ensures easy and safe access to the cutting section for quick job setups. Its short web path minimizes waste, making it particularly suitable for slitting high-value materials.