Slit, laser-perforate and inspect at 350m / minute

An integrated machine with the capability to slit, laser perforate and inspect at high speed. Micro perforation is being widely used to modify the permeability of films for packaging fresh produce such as salads, fruit and vegetables.

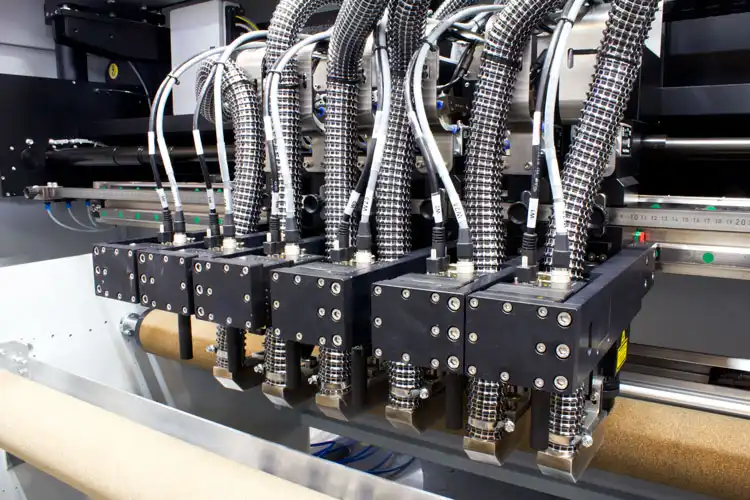

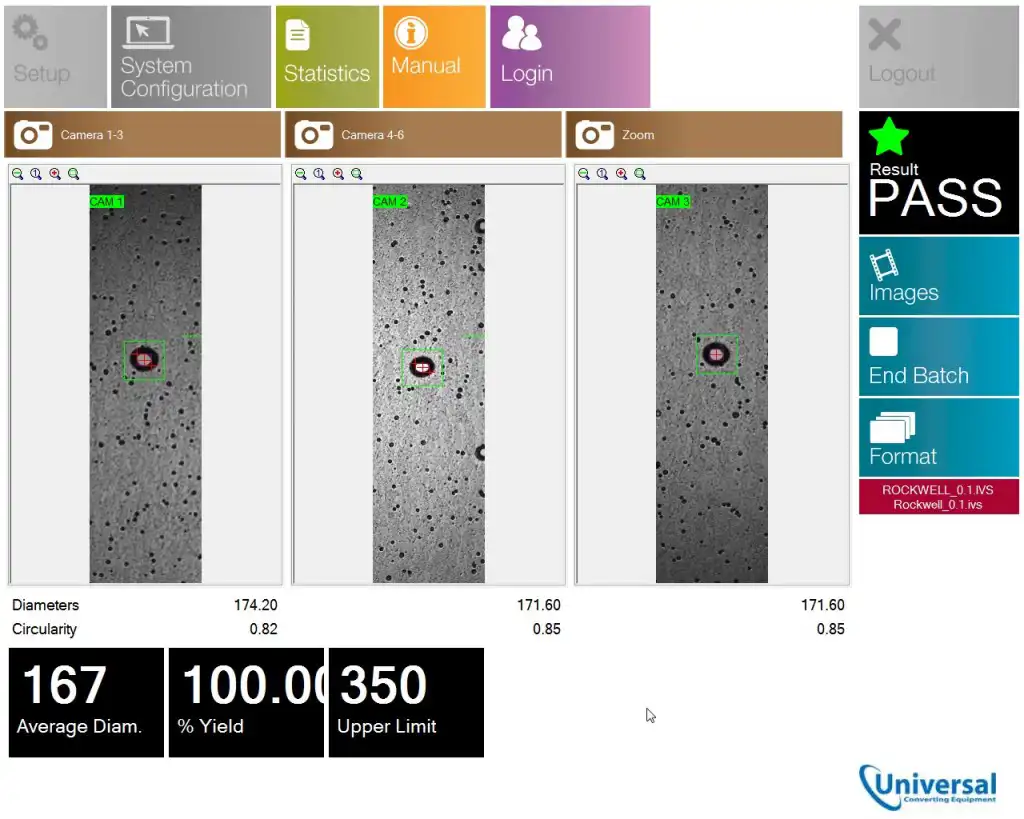

The Universal X6lp offers a fully integrated machine to produce laser perforated holes, inspect the holes produced to ensure they are the correct size and then slit the material to finished customer widths. The laser technology incorporated in the machine ensures round holes are produced at speeds of 350m/min. At these speeds, it is impossible to see the holes so a camera based inspection system measures the holes produced and a report is generated at the end of each set of rolls which can be retained for quality assurance purposes. If the measured holes are outside of the specification, the machine will alarm so corrective action can be taken.

The X6lp slitter is a high performance slitting machine with closed loop tension control and other features to ensure the ultimate in product quality and efficiency. The perforating section can have its own tension zone to optimise perforating control.

- Fully integrated system

- Laser perforate round holes at 350m/min

- Inspect perforated holes at 350m/min

- Slit and rewind with precise tension control

- Isolated tension zones

| X6LP specifications | ||

| Roll width options | 42″ 54″ 65″ 73″ 89″ | 1050mm 1350mm 1650mm 1850mm 2250mm |

| Master roll diameter options | 40″ 52″ | 1000mm 1300mm |

| Rewind diameter options | 24″ 31.5″ 40″ 42″ | 610mm 800mm 1000mm 1050mm |

| Minimum slit roll width | > 10mm > 0.39″ |

|

| Slitting options | Razor Shear Crush |

|

| Maximum speed | 350 m/min (1400 ft/min) | |

| Materials | Papers Label stock Laminates Foils Films Rubber Compound materials |

|

X6lp Slitter Gallery

| Technical Information | X | Y | ||

| Unwind diameter options Compact: Seperate: | 40″ 51″ | 1000mm 1300mm | 4000mm 6000mm |

|

| Rewind diameter options: | 26″ 34″ 44″ | 650mm 850mm 1100mm | +0mm +150mm +350mm |

|

| Web width options: | 42″ 53″ 65″ 80″ 90″ | 1050mm 1350mm 1650mm 2000mm 2250mm | 5610mm 5910mm 6210mm 6560mm 6810mm | |

| Speed options: | 1000 ft/min 2000 ft/min 2300 ft/min | 300m/min 600m/min 700m/min | ||