Automation in slitting technology is nothing new, it has evolved steadily to meet rising demands for precision, speed, and consistency. However, the challenge has been most obvious in the production of bottle labels. Narrow slit widths and demanding rewind requirements have long presented bottlenecks in efficiency. Today, those limitations are finally being overcome, thanks to advances in automation.

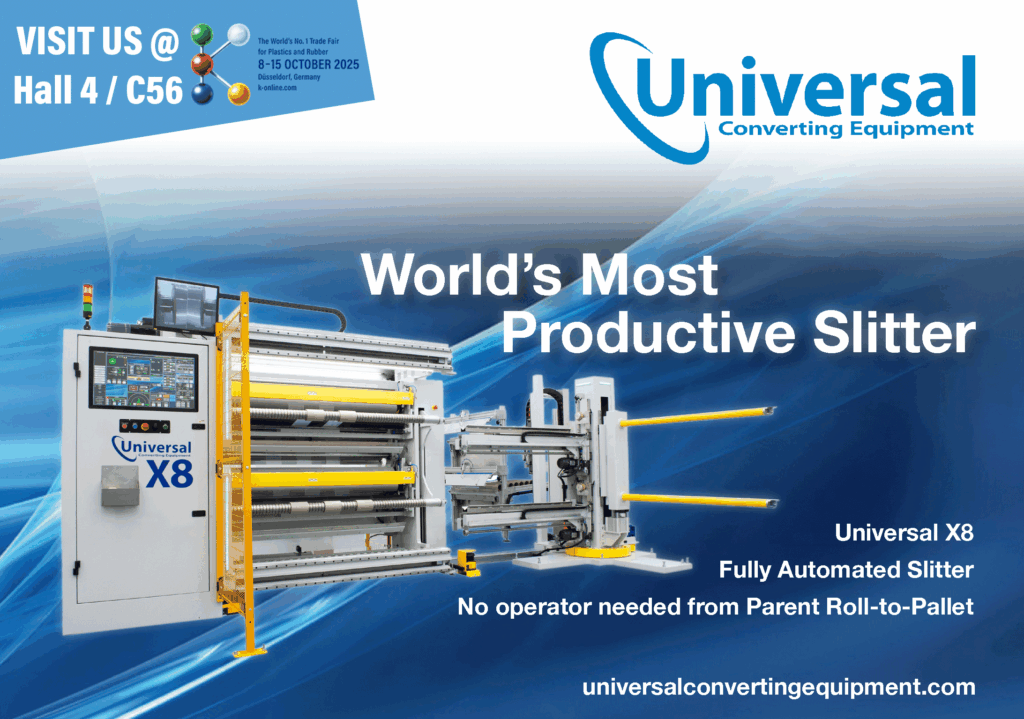

At Universal Converting Equipment, we have dedicated ourselves to building the world’s most productive slitting machines, with the highest end being the Universal X8. Over the past year, our engineering team has perfected the automation required to handle bottle label production seamlessly, from “parent roll-to-packaged pallet”, with no operator intervention. This milestone represents not only a technological leap forward but also a redefinition of what productivity and reliability look like in the converting world.

The Challenges of Bottle Labels

Bottle label production brings unique demands that conventional slitting setups struggle to meet. Labels must be slit to extremely narrow widths with high precision to ensure flawless application on high-speed bottling lines. Compounding this challenge, the industry standard requires rewind rolls on 6-inch cores, difficult to manage when adding automation with delicate, narrow webs. Historically, these two factors have necessitated significant manual oversight, slowing throughput and adding cost.

Automation at Every Step

Our latest generation of slitters is designed to eliminate those inefficiencies by automating every stage of the process. From roll closure and roll start to the automatic positioning and offloading of finished rolls, each step has been engineered to operate without operator input.

- Roll Closure & Roll Start: Automated mechanisms guarantee secure, repeatable roll builds every time. The days of manually attaching tail ends to cores to start rolls and taping down finished rolls are over.

- Automatic Roll Positioning: Narrow web rolls are positioned with pinpoint accuracy, ensuring flawless alignment on 6-inch cores without manual adjustment.

- Automated Roll Offloading: Once the rewind is complete, finished rolls are safely and quickly removed, ready for downstream packaging—again, with no operator required.

The result is a fully integrated system capable of running continuously, with productivity levels unmatched.

From Parent Roll-to-Packaged Pallet

What sets this achievement apart is the ability to truly handle the process from Parent Roll-to-Packaged Pallet. Incoming master rolls are loaded, slit, rewound, and offloaded onto conveyor systems with no human intervention. Once on a conveyor the finished rolls can be weighed, labeled, bagged and palletised automatically. By streamlining the slitting stage, converters can achieve unprecedented uptime and output, maximising the investment in post slitting automation.

Productivity Without Compromise

Automation often raises concerns about flexibility, but our technology has been built to adapt. Whether a converter is handling short runs or long campaigns, narrow widths or broader applications, the machine’s automated intelligence optimizes setup and throughput. Combined with robust mechanical engineering, this ensures not only higher speeds but also consistency and reliability, key qualities when serving the fast-moving consumer goods sector.

Redefining the Future of Slitting

The automation breakthroughs we’ve achieved represent more than just incremental improvement. They redefine what’s possible in label slitting by removing manual bottlenecks and driving true end-to-end productivity. For converters supplying bottle labels, a segment where precision, speed, and cost control are paramount, the impact is transformative.

As the demand for bottled goods continues to grow worldwide, converters now have the tools to keep pace. With fully automated slitting solutions, they can meet customer expectations with confidence while setting new standards of efficiency for the industry.

At Universal Converting Equipment, we are proud to lead this transformation. By delivering machines that combine automation, precision, and reliability, we’re helping converters move faster, smoother, and more productively than ever before.