In converting, efficiency is crucial. High-speed automated slitters like the Universal X8 process materials at remarkable speeds but can be hindered by poor-quality parent rolls. Defects in these rolls cause downtime, reduced throughput, and increased costs. Addressing these defects early is vital to peak performance.

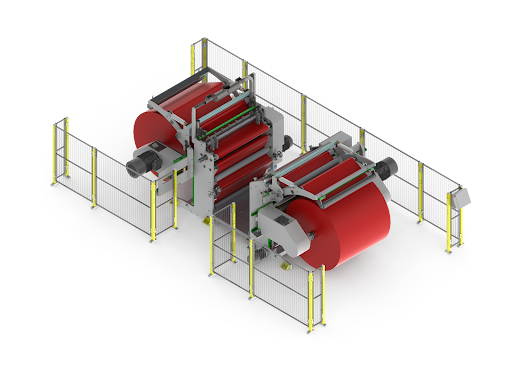

Universal Converting Equipment’s X2XL roll doctor machine offers a solution by inspecting and reworking parent rolls before slitting. This proactive approach prevents imperfections from disrupting operations, ensuring smooth processing.

Why Parent Roll Quality Matters

The principle of “quality in, quality out” applies strongly to slitting and rewinding. Even advanced systems rely on high-quality input to deliver consistent results. Wrinkles, edge damage, or printing and laminating defects in parent rolls can disrupt processing. For highly automated systems like the Universal X8, the speed and throughput amplify the impact of these problems, leading to substantial downtime. Addressing parent roll quality is essential for achieving greater efficiency.

The Role of the X2XL Roll Doctor

The X2XL simplifies preparation by correcting common roll defects. It inspects and reconditions rolls, allowing the removal of defect areas then aligning the roll properly. This reduces stoppages and ensures uninterrupted operation of high-speed slitters.

A key feature of the X2XL is its reversibility. The machine can run in either direction, which is crucial when working with printed materials. These must return to their original direction before slitting to prevent backward print. The X2XL also supports various inspection systems to identify defects and flags. It can scan entire rolls, log issues, reverse to defects, and stop for corrections. This process enables operators to produce rolls with zero flags—a key goal for efficient slitting.

The doctoring process can also involve the removal of edge trims, available as an option on this machine.

Safety and Customisation

The X2XL prioritises safety with features like the ability to pick up and lower rolls directly to the floor, reducing manual handling. It meets stringent safety standards and offers customisable safety systems tailored to customer needs. Options include physical guarding, laser safety barriers and laser area scanners, ensuring comprehensive protection.

A Holistic Approach to Efficiency

Investing in high-speed slitters like the Universal X8 is important, but ensuring material quality is equally critical. By incorporating the Universal X2XL roll doctor into workflows, businesses can maintain consistent output and maximise efficiency. A seamless combination of the X2XL and X8 ensures high-performance converting operations.

For businesses aiming to excel in automated slitting and rewinding, prioritising parent roll quality is essential. Addressing roll defects proactively creates a streamlined, efficient production process and maximises returns on equipment investments.